PRESSED AND ANODISED COMPONENTS

Turning Ideas

Into Reality

Est. 1977

IAC Limited is a manufacturer of high-quality rack anodised aluminium components for the pharmaceutical, beauty and cosmetic industries.

IAC Limited specialise in the area of deep draw transfer/progression pressing and rack anodising.

Our mission is to deliver EXPERTLY CRAFTED products that combine HIGH FUNCTIONALITY with aesthetic appeal, offering both BEAUTY AND PERFORMANCE to our customers.

Knowledge and Experience

IAC Limited’s professional technology-driven approach, along with our in-depth knowledge and experience of deep draw pressing, enables us to manufacture a wide range of components to suit standard and bespoke requirements.

We regularly introduce new pressing and anodising technology to ensure continuous improvements and innovations in the services we provide and the products we offer.

DESIGN AND DEVELOPMENT

IAC Limited we manufacturer high-quality rack anodised aluminium components for the pharmaceutical, beauty and cosmetic industries., our creative specialists treat each project as a unique challenge.

Our New Product Development team crafts innovative solutions based on customer needs. With IAC Limited, you’ll be involved from concept to final product, ensuring your vision is realised.

PRESSING

ANODISING

We continuously invest in cutting-edge anodising technology to ensure top-quality results across all projects. Our two fully-automated, computer-controlled lines offer a vast range of colours and finishes, allowing us to meet the diverse aesthetic and functional needs of our clients.

A third, semi-automatic anodising plant is dedicated to specialist production runs, offering enhanced flexibility for unique requirements or limited editions. This allows us to deliver durable, visually striking components that meet the highest quality standards.

Expertly Crafted Products

Our design and manufacturing operation is fully self-sufficient with an onsite new product development and engineering department that ensures we are able to offer flexible solutions and support short lead-times.

A TRUSTED PARTNER

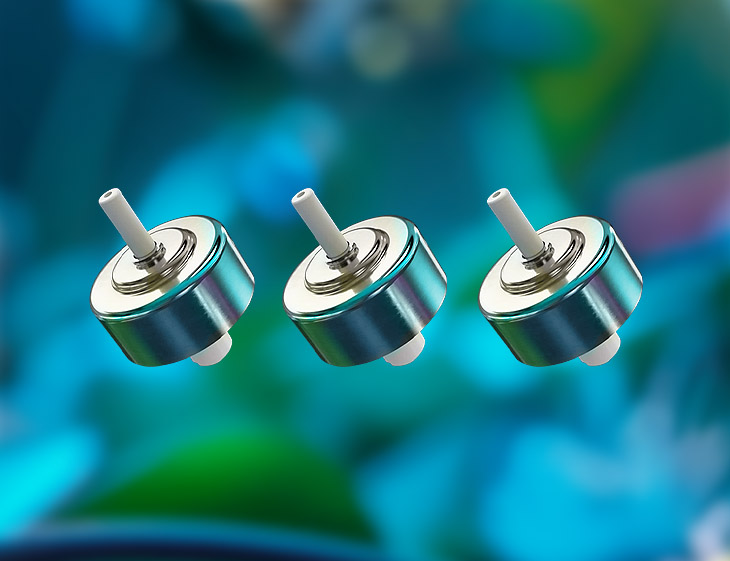

We are experts in manufacturing high-quality aluminium anodised components for the pharmaceutical industry, including inhalers, nasal sprays, and anodised cans.

With precision engineering and a commitment to quality, we are a trusted partner in delivering reliable solutions for these critical applications. Our anodising ensures finishes that meet the stringent requirements of the pharmaceutical sector.

COSMETICS

IAC Limited provides premium, stylish aluminium anodised products to the cosmetics industry, such as lipstick sleeves. Aluminium is not only more durable and eco-friendly, but it also enhances the tactile experience, adding weight and a sense of quality that resonates with high-end brands.

Our extensive range of colours, coupled with our precise colour-matching capabilities, allows us to seamlessly integrate products with the rest of a customer’s packaging. The anodising process ensures long-lasting, vibrant finishes that is resistant to wear, offering a superior performance over plastic.

QUALITY

We are committed to excellence, focusing on improving efficiency, minimising waste, and reducing costs to quickly overcome any challenges we encounter.

UK BASED MANUFACTURING

IAC Limited are a proudly UK-based company, with fast turnaround times and personalised customer support. Our UK operations ensure efficient delivery and the highest standard of quality.

WHY CHOOSE IAC?

150+ Million Capacity Per Annum

13 Deep Draw Platarg Presses

Finishes From Etched To Full Bright

2 Auto Rack

Anodising Lines

Combined: 9+ Million Per Week

3 Bruderer

High-Speed

Presses

To Meet Unique Customer Needs

Bespoke Product Development

INDUSTRIES WE SERVE

Packaging with WOW factor!

Personal Care & Cosmetics

Today’s consumers have high expectations for their personal care and beauty packaging. They seek clean ingredients, hygienic dispensing, inclusive features, and appreciate packaging that offers a touch of indulgence.

With the right design and components, your packaging can wow customers and foster lasting emotional brand loyalty.

We have solutions for:

• Droppers

• Glass and Plastic Jars

• Refillable Bottles and Jars

• Lotion and Serum Pumps

• Sustainable Packaging

Differentiate yourself from the competition

Pharmaceutical & Healthcare

Pharmaceutical packaging must prioritise safety, reliability, and convenience. It needs to safeguard the product during manufacturing and distribution, while maintaining its efficacy throughout its shelf life.

Safety comes first. Packaging must provide sufficient label space for product details, incorporate child-resistant features when necessary, and ensure accurate dosing.

Our solutions include:

• Pipettes

• Caps and Closures

• Glass Bottles

• TE and CRC Closures

• Vials

Make an impact!

Perfume & Fragrance

Whether classic or bold, the right fragrance packaging sets your brand apart, with striking design being more crucial than ever in the competitive fragrance market.

Our premium packaging solutions provide the perfect canvas to tell your brand’s story through innovative shapes, textures, metallisation, frosted finishes, and other design elements.

We have solutions for:

• Glass Bottles

• Pumps and Atomisers

• Caps and Closures

• Sustainable Solutions

Elevate your brand and boosts sales

Home Fragrance

With a wide variety of home fragrances available, customers have endless options to refresh their living space. In the competitive home fragrance market, packaging plays a pivotal role in standing out.

As first impressions are more important than ever, fragrance packaging has evolved into an art, blending aesthetics with innovation.

We have solutions for:

• Glass Bottles

• Pumps and Atomisers

• Caps, Closures and Shrouds

• Sustainable Solutions

Shelf appeal and product protection, that delivers

Nutraceuticals & Healthcare

From vitamins and minerals to supplements, The Lendlock Group offers packaging solutions tailored to today’s Nutraceutical and Healthcare consumers.

With our expertise, we identify the ideal packaging solutions to meet the unique needs of your products.

We have solutions for:

• Plastic and Glass Bottles

• Droppers

• TE and CRC Closures

• Sustainable Packaging

Enhance your product integrity and brand trust

Household

From surface cleaners and detergents to gardening products, we provide stylish packaging solutions for every at-home need.

Household packaging must convey product effectiveness while delivering convenience. We offer options for every area of the home.

We have solutions for:

• Pumps, Trigger and Sprayers

• Caps and Closures

• Wipes Canisters

• Plastic and Glass Bottles

• Sustainable Packaging

Talk to Us

Whether you’re looking for a glass bottle or a simple closure the Lendlock Group have a proven track record and over 60 years of experience to help you find exactly what you’re looking for.

Certification

We are fully certified to the ISO 9001 quality standard and we offer consistency across all processes driven environment that adheres to the strictest requirements. We recognise the importance of Health & Safety within the workplace as well as minimising the impact we have on our environment.

Achieving accreditation to ISO 4001 reafirms our commitment to exceeding the stringent environmental standards within our own company and the wider community in which we operate. Our pledge to achieve ISO 8001 demonstrates our aim to embed a strong safety culture for all employees and visitors. We care for our products, the environment and the people that live in it.